The electric scooter market has witnessed exponential growth over the last few years, with the global market size expected to reach $41.98 billion by 2027, according to a report by Fortune Business Insights. This surge in popularity raises concerns about the sustainability and performance of standard electric scooter parts. Many riders encounter issues with the durability and efficiency of these components, leading to a growing interest in alternative electric scooter parts. As reported by marketsandmarkets.com, the demand for high-performance components is on the rise, with a projected CAGR of 20.4% from 2021 to 2026. By exploring innovative materials and designs, manufacturers can enhance the overall performance and lifespan of electric scooters, addressing common problems associated with traditional parts.

This blog will delve into the nuances of alternative electric scooter parts and their potential to revolutionize the rider experience.

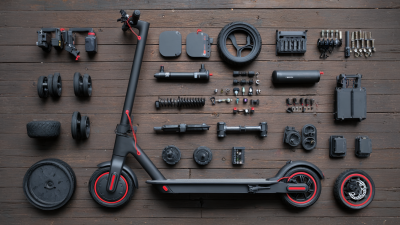

Upgrading the components of your electric scooter can significantly enhance its performance and longevity. By investing in higher-quality parts, such as batteries, motors, and tires, you can experience improved speed, better handling, and overall reliability. For example, a lithium-ion battery can provide longer range and faster charging times compared to standard options. This means more time riding and less time waiting for a recharge, allowing you to fully enjoy your commuting experience.

**Tips:** When considering upgrades, prioritize parts that align with your riding habits. If you often ride on rugged terrain, opt for robust tires that can withstand wear and tear. For daily commuters, a high-performance motor can provide the extra power needed to tackle hills and longer distances with ease. Always ensure that the components are compatible with your specific scooter model to avoid any potential issues.

Another benefit of upgrading is the potential for reduced maintenance costs over time. By replacing stock components with durable alternatives, you can minimize the frequency of repairs. This proactive approach not only enhances your scooter's capabilities but also saves money in the long run.

**Tips:** Research and read reviews on aftermarket parts before purchasing. Look for reputable brands that offer warranties, as this can be indicative of quality and reliability. Joining online forums can also provide useful insights and recommendations from experienced riders who have successfully upgraded their scooters.

As the electric scooter market continues to expand, the demand for enhanced durability in scooter parts has become paramount. Recent studies indicate that the global electric scooter market is expected to reach over $40 billion by 2030, highlighting the importance of maintaining high performance standards through innovative materials. This push has led manufacturers to explore alternative materials such as carbon fiber and advanced thermoplastics, which offer significantly improved strength-to-weight ratios compared to traditional metals.

Research conducted by the International Journal of Engineering Materials emphasizes that components made from high-performance polymers can withstand greater stress and environmental conditions, translating into longer-lasting parts that require less frequent replacements. For instance, using reinforced composites in the construction of scooter frames and wheels can reduce the weight by up to 30%, while simultaneously increasing impact resistance. Furthermore, incorporating weather-resistant coatings has proven to enhance the lifespan of electric scooter components, ensuring they can endure the rigors of daily use and varying weather conditions. These innovations not only bolster the durability of electric scooters but also enhance their overall performance, making them a more reliable choice for consumers.

| Part Type | Material | Weight (kg) | Durability Rating (1-10) | Cost ($) |

|---|---|---|---|---|

| Handlebar | Aluminum Alloy | 1.2 | 8 | 50 |

| Deck | Fiberglass-Reinforced Plastic | 2.0 | 9 | 70 |

| Wheels | PU (Polyurethane) | 0.5 | 7 | 30 |

| Battery Case | Carbon Fiber | 1.5 | 10 | 150 |

| Brakes | Ceramic Composite | 0.8 | 9 | 45 |

Customizing your electric scooter can significantly enhance both its performance and durability, making it a worthwhile investment for riders seeking a more enjoyable experience. One of the key components to consider is the battery. According to a report by Statista, the average lifespan of electric scooter batteries is around 2-3 years, with degradation potentially reducing performance over time. Upgrading to a lithium-ion battery can offer longer lifespans and better energy density, leading to improved range and efficiency. Riders can also explore options like battery management systems to optimize charging cycles and prolong battery health.

Another critical part to consider is the motor. A high-performance brushless DC motor can boost your scooter's acceleration and top speed. Research by the National Renewable Energy Laboratory indicates that scooters equipped with more powerful motors can reach speeds exceeding 30 mph, providing a thrilling ride for enthusiasts. Furthermore, enhancing your scooter’s braking system with hydraulic disc brakes ensures better stopping power, especially when riding at higher speeds. As e-scooter use becomes more prevalent, focusing on these customized parts can lead to a safer and more exhilarating ride, tailoring your electric scooter to fit your specific needs and preferences.

When it comes to electric scooters, weight and design significantly influence their overall efficiency. Lighter electric scooters tend to offer better performance, particularly in urban environments where agility is key. Recent studies show that minimizing the weight of an e-scooter can enhance its acceleration and braking capabilities, making commuting more efficient. Cities embracing micro-mobility solutions have also reported improvements in user satisfaction linked to well-designed, lightweight scooters. These scooters are more energy-efficient, allowing for longer rides on a single charge, which is essential for users seeking sustainable transportation options.

Moreover, the design aspect goes hand in hand with performance. A well-thought-out design can facilitate aerodynamics and better weight distribution, reducing drag and improving speed. Innovations such as fuel cell technology are pushing the boundaries of e-scooter range and efficiency, demonstrating that engineering improvements can lead to significant strides in performance. As cities increasingly adopt electric scooters for cleaner transport, optimizing both weight and design will be critical for enhancing utility and paving the way for a sustainable future in urban travel.

As the electric scooter market continues to expand, the focus on sustainable manufacturing practices is becoming more critical. Traditional production methods often lead to waste and environmental degradation, prompting manufacturers to seek innovative solutions. Future trends indicate a shift towards using recycled materials and bio-based composites in the production of electric scooter parts. This not only reduces the carbon footprint associated with manufacturing but also promotes a circular economy where materials are reused and repurposed.

Additionally, advancements in technology are making it possible to create lightweight yet durable parts that enhance overall scooter performance. For example, 3D printing is garnering attention for its ability to produce customized components with minimal waste. Such innovations profoundly impact how parts are designed, allowing for greater efficiency and personalization. As electric scooter manufacturers embrace these sustainable practices, the industry is likely to see enhanced longevity in products, reducing the frequency of replacements and ultimately benefiting both consumers and the planet.