The global electric scooter market has witnessed remarkable growth, with a projected increase in value from $18.6 billion in 2020 to an estimated $41.4 billion by 2027, according to a recent report by Fortune Business Insights. This surge in demand has created a pressing need for high-quality Electric Scooter Parts, making it essential for manufacturers and retailers to source from reliable suppliers worldwide.

The global electric scooter market has witnessed remarkable growth, with a projected increase in value from $18.6 billion in 2020 to an estimated $41.4 billion by 2027, according to a recent report by Fortune Business Insights. This surge in demand has created a pressing need for high-quality Electric Scooter Parts, making it essential for manufacturers and retailers to source from reliable suppliers worldwide.

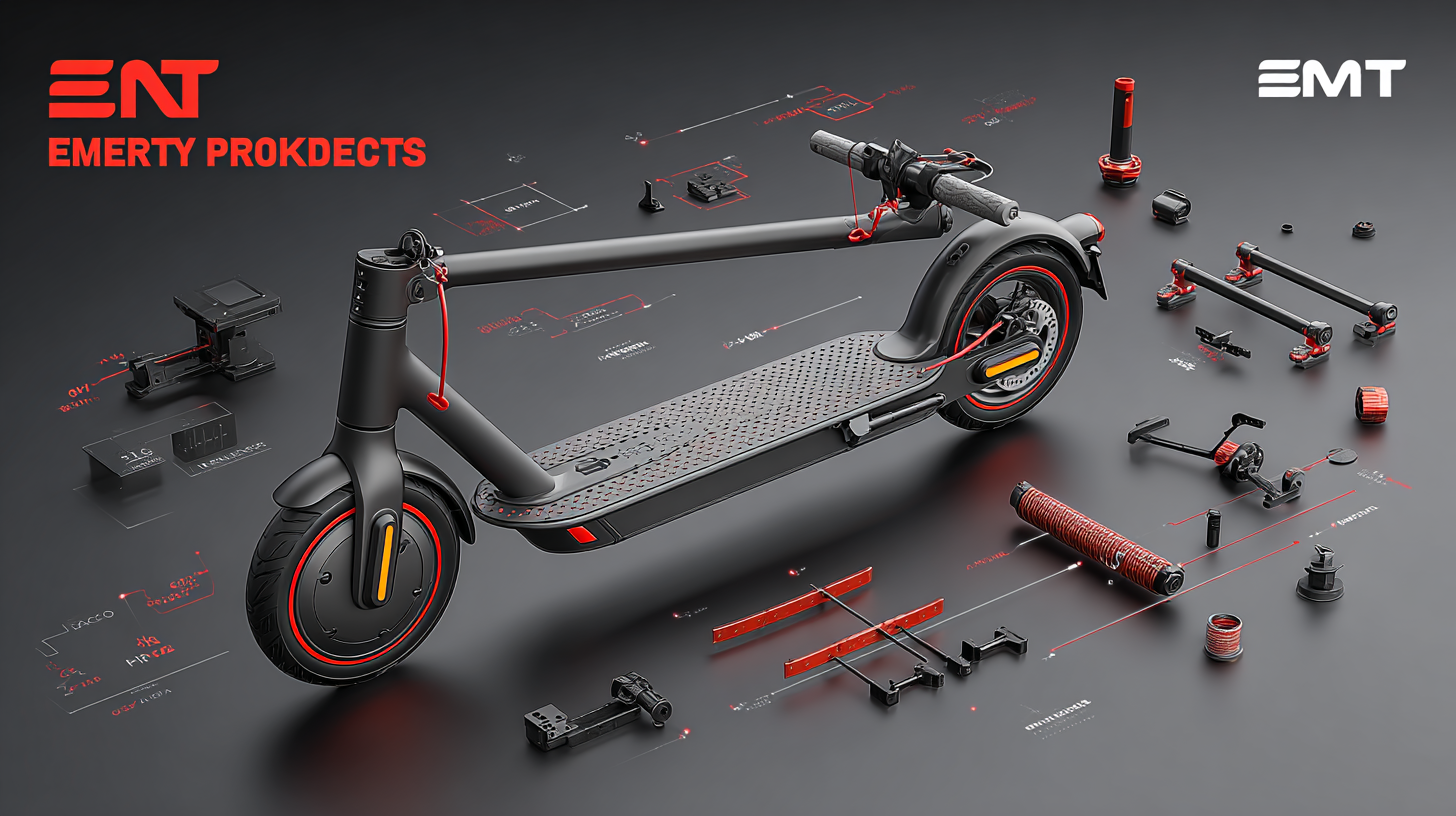

As electric scooters become a preferred mode of transportation, ensuring the availability of premium components is crucial for maintaining vehicle performance and safety. The right suppliers not only provide durable and innovative parts but also offer competitive pricing and efficient delivery solutions.

In this blog, we will explore effective strategies for identifying and securing top-tier Electric Scooter Parts suppliers globally, revealing the secrets to navigating this dynamic market successfully.

When sourcing premium electric scooter parts suppliers globally, it's essential to identify key criteria that set top-tier suppliers apart. According to a recent report by MarketsandMarkets, the electric scooter market is projected to reach $41.98 billion by 2030, emphasizing the increasing demand for high-quality components. Suppliers must adhere to strict quality standards and utilize advanced materials that ensure durability and safety, as these are critical for sustaining consumer trust in a competitive market.

**Tip:** Always vet suppliers based on their certifications and compliance with international quality standards such as ISO 9001. This ensures that the parts you source meet the necessary safety and performance benchmarks.

Furthermore, evaluating a supplier's technological capabilities is crucial. As the industry evolves, innovations such as lightweight materials and integrated smart technologies are becoming standard. A report by Grand View Research illustrated that 35% of manufacturers prioritize suppliers with robust R&D capacities. This focus on innovation can significantly enhance the performance of electric scooters, catering to the tech-savvy consumer base.

**Tip:** Consider conducting site visits or virtual assessments to gauge a supplier's infrastructure and R&D environment, ensuring they can keep pace with the rapidly changing landscape of electric scooter technology.

| Supplier Location | Experience (Years) | Product Range | Certification | Minimum Order Quantity | Lead Time (Weeks) |

|---|---|---|---|---|---|

| China | 10 | Motors, Batteries, Frames | ISO 9001 | 100 | 4 |

| Taiwan | 8 | Controllers, Tires, Accessories | CE, RoHS | 300 | 6 |

| Germany | 15 | Brakes, Lights, Custom Parts | TÜV | 50 | 3 |

| USA | 12 | Frames, Motors, Electronics | UL, ISO 9001 | 200 | 5 |

| India | 5 | Batteries, Accessories | ISO 14001 | 150 | 8 |

When it comes to sourcing premium electric scooter parts, exploring global markets is crucial. Countries like China, Taiwan, and South Korea are renowned for their advanced manufacturing capabilities and competitive pricing.

China, in particular, is home to numerous suppliers that specialize in electric scooter components, including batteries, motors, and controllers. By attending trade fairs such as the Canton Fair or visiting manufacturing hubs like Shenzhen, buyers can connect directly with prolific manufacturers, gaining insights into product quality and customization options.

Additionally, Europe has emerged as a significant player in the electric scooter parts market. Countries like Germany and the Netherlands are known for their high standards of engineering and quality control. Collaborating with European suppliers can offer advantages in compliance with strict regulations and environmentally-friendly manufacturing processes.

By leveraging online platforms and industry networks, buyers can navigate these global markets effectively, ensuring they source durable and reliable parts that meet their specific requirements.

When it comes to sourcing premium electric scooter parts, evaluating quality and reliability is paramount. According to a report by ResearchAndMarkets, the global electric scooter market is projected to grow at a CAGR of 7.7% through 2025, leading to an increased demand for reliable components. Suppliers must meet stringent quality standards to ensure safety and performance. For instance, the production of lithium-ion batteries, which are critical for e-scooters, requires adherence to ISO 9001 quality management principles to mitigate risks associated with battery failure.

In the quest for quality sourcing, suppliers should be assessed based on their adherence to international compliance regulations such as CE and UL certifications. Industry reports indicate that products passing these certifications experience lower defect rates and higher consumer satisfaction. Moreover, utilizing platforms like Alibaba or specialized directories like ThomasNet can help in filtering suppliers based on ratings and customer reviews, ultimately paving the way for securing components that enhance the longevity and dependability of electric scooters.

Investing time in these evaluations not only ensures quality but also strengthens the supply chain against potential disruptions.

Building strong relationships with suppliers is essential for long-term success in the electric scooter parts industry. As companies increasingly prioritize transparency as a core business value, they find that this openness fosters consumer trust and loyalty. Research indicates that 70% of consumers are more likely to engage with brands that demonstrate transparency. Establishing a solid foundation of trust not only enhances supplier relationships but also contributes to a resilient supply chain.

Building strong relationships with suppliers is essential for long-term success in the electric scooter parts industry. As companies increasingly prioritize transparency as a core business value, they find that this openness fosters consumer trust and loyalty. Research indicates that 70% of consumers are more likely to engage with brands that demonstrate transparency. Establishing a solid foundation of trust not only enhances supplier relationships but also contributes to a resilient supply chain.

To strengthen these partnerships, companies should prioritize consistent communication and collaboration. Regular check-ins and feedback loops can enhance understanding and alignment between both parties. According to industry reports, businesses that invest in supplier partnerships see a 20% increase in operational efficiency.

Tips:

Navigating international sourcing for premium electric scooter parts in 2025 presents a myriad of challenges, particularly within the backdrop of escalating trade regulations and logistics complexities. As tariffs and trade barriers rise, businesses must adapt to evolving global trade policies that can significantly impact procurement strategies. Understanding these regulatory landscapes requires a proactive approach to compliance and an ability to swiftly pivot sourcing decisions in response to geopolitical tensions and regulatory shifts.

Logistical intricacies are compounded by climate change, technological vulnerabilities, and resource scarcity, necessitating a robust and resilient supply chain. Companies engaged in international trade must develop strategic relationships with suppliers while closely monitoring shifting geopolitical dynamics that could disrupt supply lines. Leveraging technology and data analytics can provide valuable insights, helping organizations make informed decisions that enhance operational efficiency and reduce costs amid these challenges. By staying informed and agile, businesses can unlock the potential of global sourcing, securing high-quality parts that meet their evolving needs.