Electric scooter, scooter hub motor and wear-resistant silent gear transmission

In the application of plastic planetary gears in hub motors of electric scooters, scooters, and electric-assisted bicycles, Suzhou Weiben Engineering Plastics Wintone Z33 wear-resistant and silent gear special material can help solve the problem of insufficient wear resistance, fatigue resistance, and noise of traditional nylon materials. Large, torque and size are greatly affected by moisture, leading to problems such as insufficient stability.

What is short-term transportation? Short-term transportation refers to trips of less than 3 kilometers. Global short-term transportation is in a period of rapid development driven by supply, with a definite trend of industrial upgrading. Due to its production advantages in batteries and motors, my country will gain strong industrial advantages in the field of short-term transportation.

Before the large-scale application of lithium batteries, cheap and reliable batteries were mainly lead-acid batteries and nickel-metal hydride batteries. Their common characteristics are: small charge capacity, not durable, and difficult to create competitive products. Product innovation for short-term transportation was slow during this period. Between 2010 and 2015, the cost of lithium batteries dropped by nearly 70%, entering the stage of large-scale application. Around 2015, the application of lithium batteries ushered in long-lost innovations in the field of short-term transportation, and many innovations such as electric scooters and electric-assisted bicycles emerged. Now yuema and everyone will learn about one of the main representatives of short-term transportation: electric scooters.

Electric scooter for short transportation

If you pay a little attention, starting from 2016, more and more new electric scooters have come into our view. In the following years of 2016, electric scooters entered a period of rapid development, bringing short-term transportation to a new stage. According to some public data, it can be estimated that global electric skateboard sales in 2020 will be around 4-5 million, making it the fourth largest micro-mobility tool in the world after bicycles, motorcycles and electric bicycles. Electric scooters have a history of more than 100 years, but sales have only exploded in recent years. This is closely related to the application of lithium batteries. Portable travel tools such as electric scooters can be carried on the subway and into the office. They can only be competitive if they are light enough. Therefore, before the application of lithium batteries, it is difficult for the B-side and C-side of electric scooters to have vitality. At present, electric scooters still maintain rapid development and are expected to become the mainstream short-term transportation tool in the future.

Scooters became popular during World War I, in part because they were very fuel-efficient and provided transportation for many people who couldn't afford cars or motorcycles.

Some businesses also experimented with the novel device, such as the New York Postal Service, which used it to deliver mail.

In 1916, four special delivery carriers with the United States Postal Service were trying out their new tool, a scooter called an Autoped.

The scooter craze was all the rage for a while, however, shortly after the end of World War I, electric scooters began to fade away. Its practicality has been challenged, such as weighing over 100 pounds (90.7 pounds) and making it difficult to carry.

On the other hand, as is the case now, some road sections are not suitable for scooters, and some road sections prohibit scooters.

Even in 1921, American inventor Arthur Hugo Cecil Gibson, one of the inventors of the scooter, gave up on making improvements to the two-wheelers, considering them obsolete.

History has come to this day, and there are various types of electric scooters today.

The most common shape of electric scooters is the L-shape. It has an integrated frame structure and is designed in a minimalist style. The handlebar can be designed in a curved shape or a straight shape. The steering column and the handlebar are generally at an angle of about 70°, which can show the beauty of the curves of the combined assembly. After folding, the electric scooter has a "one-line" structure. On the one hand, it can present a simple and beautiful folded structure, and on the other hand, it is easy to carry.

Electric scooters are loved by everyone. In addition to their appearance, they also have many advantages: Portability: Electric scooters are generally smaller in size, and their bodies are generally made of aluminum alloy. They are lightweight and portable. Compared with electric bicycles, You can easily put the electric scooter into the trunk of your car, or take it with you on the subway, bus, etc. It can be used in combination with other means of transportation, which is very convenient.

Environmental protection: It can meet the needs of low-carbon travel. Compared with cars, there is no need to worry about urban traffic jams and parking difficulties. Highly economical: Electric scooters are powered by lithium batteries, which have long battery life and low energy consumption. Efficient: Electric scooters generally use permanent magnet synchronous motors or brushless DC motors. The motors have large output, high efficiency, and low noise. They generally have a maximum speed of more than 20km/h, which is much faster than shared bicycles.

The components of an electric scooter

There are more than 20 parts in all electric scooters. Of course, these are not all. There is also a motor control system motherboard inside the body.

The motor of an electric scooter generally uses a brushless DC motor or a permanent magnet synchronous motor of several hundred watts and is matched with a special controller. The brake control generally uses cast iron or composite steel; lithium batteries have a variety of capacities and can be customized according to your actual needs. Choose, if you have certain requirements for speed, try to choose a battery above 48V; if you have requirements for cruising range, try to choose a battery with a capacity above 10Ah. The body structure of an electric scooter determines its load-bearing strength and weight. It must have a load-bearing capacity of at least 100 kilograms to ensure that the scooter is strong enough to withstand the test on bumpy roads. At present, the most commonly used material for electric scooters is aluminum alloy, which is not only relatively light in weight, but also excellent in sturdiness.

The instrument panel can display information such as current vehicle speed and mileage, and a capacitive touch screen is generally selected; tires generally come in two types: tubeless tires and pneumatic tires, with tubeless tires being relatively expensive; for lightweight design, the frame is generally made of aluminum alloy.

Analysis of the core technology of electric scooters

If the components of an electric scooter are broken down and evaluated one by one, the cost of the motor and control system is the highest. At the same time, they are also the "brain" of the electric scooter. The start, operation, advance and retreat, speed, and stop of the electric scooter depend on are all motor control systems in scooters.

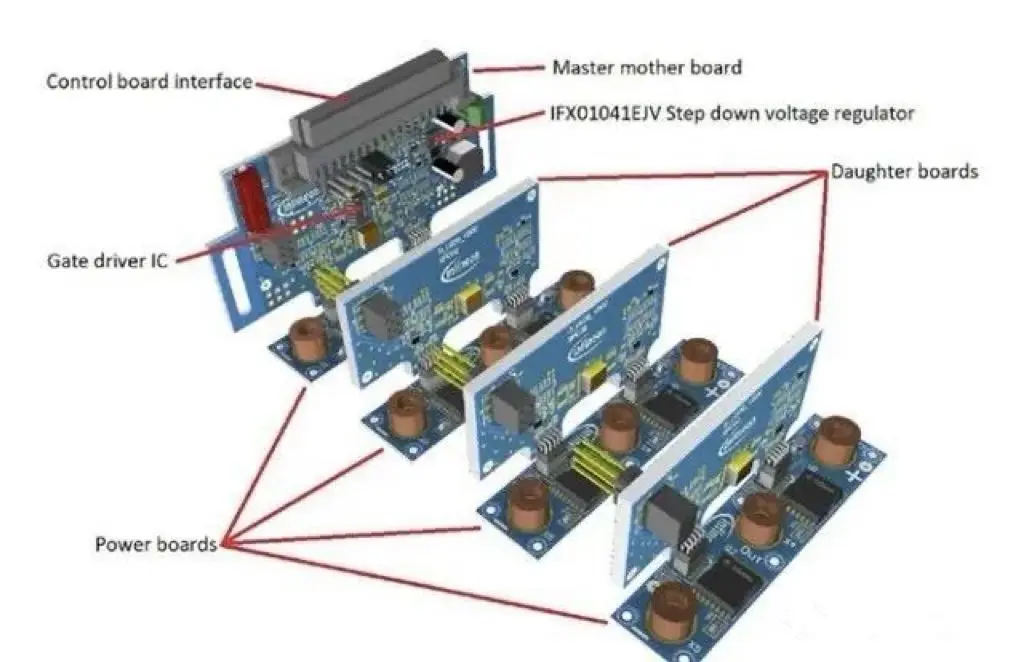

Electric scooters can operate quickly and safely, which requires high performance of the motor control system and high efficiency of the motor. At the same time, as a practical means of transportation, the motor control system is required to withstand vibration, endure harsh environments, and have high reliability. The conventional scooter control system hardware design is shown in the figure below, which mainly includes drive MCU, gate drive circuit, MOS drive circuit, motor, Hall sensor, current sensor, speed sensor and other modules.

The MCU works through the power supply and uses the communication interface and charging module to communicate with the power supply and power module. The gate drive module is electrically connected to the main control MCU and drives the BLDC motor through the OptiMOSTM drive circuit. The Hall position sensor can sense the current position of the motor, and the current sensor and speed sensor can form a double closed-loop control system to control the motor.

After the motor starts running, the Hall sensor senses the current position of the motor, converts the position signal of the rotor magnetic pole into an electrical signal, and provides the electronic commutation circuit with correct commutation information to control the switching of the power switch tube in the electronic commutation circuit. status and feeds the data back to the MCU. The current sensor and the speed sensor form a double closed-loop system. When the speed difference is input, the speed controller will output the corresponding current. Then the difference between the current and the actual current is used as the input of the current controller, and then the corresponding PWM is output to drive the permanent magnet rotor. Continuously rotates for reversing control and speed control. The use of a double closed-loop system can enhance the anti-interference performance of the system. The double-closed loop system increases the feedback control of the current, which can reduce the overshoot and oversaturation of the current and obtain better control effects, which is the key to the smooth movement of the electric scooter.

Additionally, some scooters are equipped with electronic anti-lock braking systems. The system detects the wheel speed by sensing the wheel speed sensor. If it detects that the wheel is locked, it automatically controls the braking force of the locked wheel so that it is in a rolling and sliding state (the sideslip rate is about 20%). ), ensuring the safety of electric scooter owners.

Additionally, some scooters are equipped with electronic anti-lock braking systems. The system detects the wheel speed by sensing the wheel speed sensor. If it detects that the wheel is locked, it automatically controls the braking force of the locked wheel so that it is in a rolling and sliding state (the sideslip rate is about 20%). ), ensuring the safety of electric scooter owners.

In the control system board, the MCU is placed in the middle of the circuit board, and the door drive circuit is placed slightly away from the MCU. When designing, attention should be paid to the heat dissipation of the door drive circuit. Screw terminal power connectors are provided on the power strip to allow for high current interconnection via copper terminal strips. For each phase of output, two copper strips form a DC bus connection, connecting all parallel half-bridges of that phase to the capacitor bank and the DC supply. Another copper strip is connected in parallel to the output of the half-bridge.