How to ensure the accuracy of electric scooter battery testing?

How to ensure the accuracy of electric scooter battery testing?

The accuracy of electric scooter battery testing is crucial to evaluating battery performance, extending service life, and ensuring safety. The following are key steps and suggestions to ensure test accuracy:

1. Choose the right test standard

Electric scooter battery testing should follow relevant international and national standards, such as IEC 62133, GB 31241, UN 38.3 or UL 1642. These standards cover multiple aspects such as the battery's electrical performance, safety performance, and environmental adaptability, ensuring that the test is comprehensive and meets industry requirements.

2. Use high-precision test equipment

The accuracy of the test equipment directly affects the accuracy of the test results. For example, when conducting battery capacity testing, a high-precision charge and discharge tester should be used, and the equipment should be calibrated regularly. In addition, the temperature control equipment of the test environment (such as a constant temperature box) should also have high accuracy to simulate the performance of the battery at different temperatures.

3. Control the test environment

The temperature and humidity of the test environment have a significant impact on battery performance. It is recommended to test under standard environmental conditions (such as 25℃±1℃). For high and low temperature tests, the temperature range should be set strictly in accordance with the standard (such as -40℃ to 80℃), and the test environment should be stable.

IV. Standardized test process

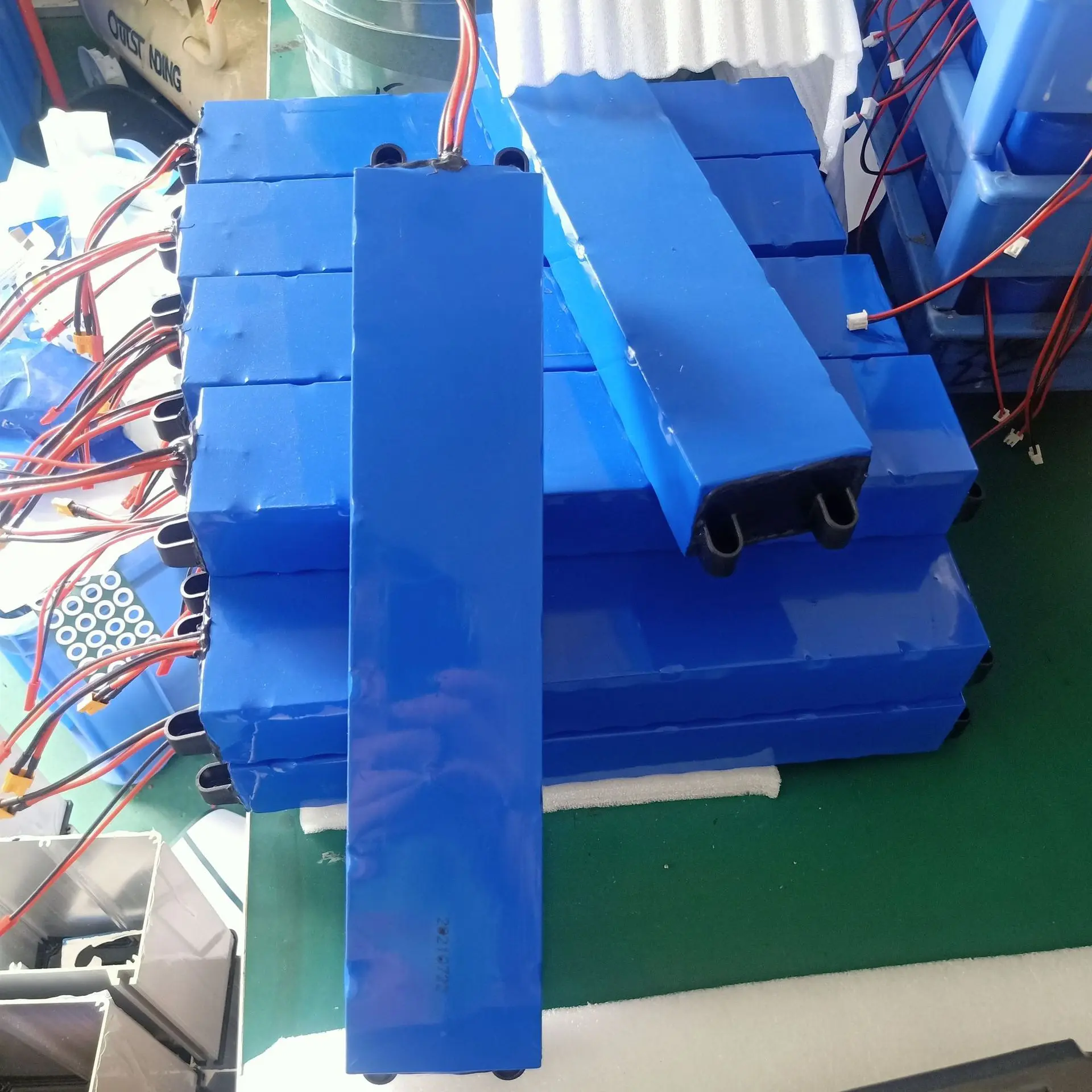

Sample preparation: Select representative battery samples to ensure that the number of samples is sufficient and in good condition.

Pre-test inspection: Perform a visual inspection of the battery before testing to ensure that there is no expansion, deformation or damage.

Charge and discharge test: Use constant current and constant voltage charging and constant current discharge mode to record the voltage, current and time data during the test.

Cycle life test: Evaluate the capacity retention rate of the battery through multiple charge and discharge cycles.

Safety performance test: Including overcharge, short circuit, extrusion and other tests to simulate the safety of the battery under extreme conditions.

V. Professional laboratory and certification

It is recommended to send the battery to a qualified professional laboratory for testing, such as a laboratory certified by IEC, UL or KC. These laboratories have advanced testing equipment and professional technical teams, which can provide accurate and reliable test results and issue authoritative test reports.

VI. Data analysis and calibration

After the test is completed, the data should be analyzed in detail to ensure the accuracy and repeatability of the results. At the same time, the test equipment should be calibrated and maintained regularly to ensure the long-term stability of the equipment.

By following the above steps, the accuracy of the electric scooter battery test can be effectively ensured, providing a reliable basis for the safe use and performance evaluation of the battery.